Advanced High Frequency Equipment for Efficient Mineral Separation and Screening

Overview Package Size6000.00cm * 2400.00cm * 2800.00cm Package Gross Weight15000.000kg Discover unparalleled shipping ve

Send your inquiryDESCRIPTION

- Overview

- Product Description

- Detailed Photos

- Product Parameters

- Certifications

- Packaging & Shipping

- Our Advantages

- Company Profile

- FAQ

Basic Info.

| Model NO. | Linear vibrating screen |

| Transmission Structure | Eccentric Vibrating Screen |

| Usage | Sieve Sand and Gravel |

| Works | Rotary Vane Shaker |

| Object | Sand Aggregate Mines |

| Shaft Number | Double |

| Running Track | Linear Vibrating Screen |

| Supporting Device | Rubber Spring |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1year |

| Processing Capacity (T/H) | 0-300 |

| Place of Origin | Shandong, China |

| Dimension(L*W*H) | We Can Customized |

| Weight | 3000 Kg |

| Brand Name | Lusheng |

| Video Outgoing-Inspection | Provided |

| Voltage | 220/380/660V |

| Feed Size | 0-50mm |

| Application | Ore |

| Machinery Test Report | Provided |

| Transport Package | Standard -Nude Packing |

| Specification | LDT3645 |

| Trademark | Lusheng |

| Origin | Binzhou, China |

| HS Code | 8474100000 |

| Production Capacity | 30000kg/Month |

Packaging & Delivery

Package Size6000.00cm * 2400.00cm * 2800.00cm Package Gross Weight15000.000kgProduct Description

Product Description

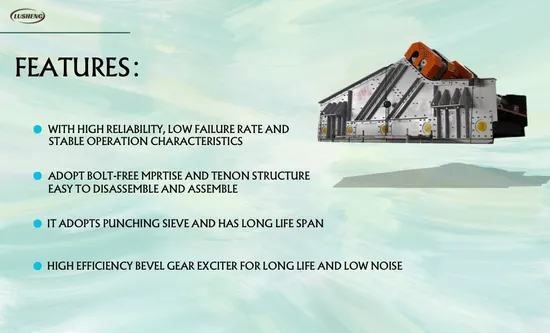

Introducing the Customizable High Frequency Linear Mining Screen, a true marvel of engineering, meticulously crafted to achieve extraordinary results in the essential processes of dehydration, desliming, and desludging. This versatile and innovative equipment stands as the quintessential solution for a diverse array of industries including sand and stone plants, coal preparation facilities, and tailing dry discharge operations. Celebrated across industry circles under various monikers such as the sand and stone dewatering screen, mine dewatering screen, coal slime dewatering screen, or tailing dewatering screen, it symbolizes superior performance and steadfast reliability. Its unrivaled efficiency seamlessly tackles a wide spectrum of dewatering challenges, ensuring operations run smoothly and effectively with unparalleled ease.

Detailed Photos

Model Number: ZSK-1224, ZSK-1530, ZSK-2040 Applicable Industry: This innovative piece of high-frequency technology is designed to expertly meet the diverse and intricate demands of a wide range of industries. With its advanced capabilities, it excels in the processing of tailings from essential minerals, including iron, gold, copper, vanadium, lead-zinc, and graphite. It also showcases remarkable efficiency in sand washing applications, making it the perfect choice for industries involved with quartz, zircon, glass, construction materials, casting, and more. Beyond these, it holds a critical position in sewage treatment endeavors, effectively addressing the challenges of municipal, industrial, and river sludge projects. Working Principle: The secret to its superior performance lies in its groundbreaking double motor drive self-synchronization technology. This state-of-the-art screen provides a precise and consistent reciprocating linear motion, ensuring impeccable operational synergy. Its meticulously crafted V-shaped structure delivers unmatched dehydration results, establishing itself as an invaluable resource that greatly enhances efficiency and productivity throughout your industrial processes.

Product Parameters

| Model | Width×Length (m) | Cover Surface (m2) | Sieve Plate Structure | Screen Size (mm) | Feed Size (mm) | Capacity (t/h) | Power (kw) | Weight (kg) |

| LDT2461 | 2.4×6.1 | 14.64 | 1,2,3,4,5 | 0.5-13 | ≤50 | 85-130 | 30 | 15200 |

| LDT3045 | 3.0×4.5 | 13.5 | 1,2,3,4,5 | 0.5-13 | ≤80 | 95-360 | 37 | 14200 |

| LDT3052 | 3.0×5.2 | 15.6 | 1,2,3,4,5 | 0.5-13 | ≤80 | 110-360 | 45 | 14830 |

| LDT3061 | 3.0×6.1 | 18.3 | 1,2,3,4,5 | 0.5-13 | ≤80 | 130-420 | 45 | 16200 |

| LDT3645 | 3.6×4.5 | 16.2 | 1,2,3,4,5 | 0.5-13 | ≤80 | 150-480 | 45 | 17520 |

| LDT3661 | 3.6×6.1 | 21.96 | 1,2,3,4,5 | 0.5-13 | ≤80 | 180-550 | 45 | 19820 |

| LDT3673 | 3.6×7.3 | 26.3 | 1,2,3,4,5 | 0.5-13 | ≤80 | 200-600 | 45 | 21200 |

| 2LDT2461 | 2.4×6.1 | 2×14.64 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤80 | 100-320 | 37 | 20300 |

| 2LDT3045 | 3.0×4.5 | 2×13.5 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤80 | 125-550 | 45 | 19520 |

| 2LDT3052 | 3.0×5.2 | 2×15.6 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤80 | 130-580 | 55 | 18300 |

| 2LDT3061 | 3.0×6.1 | 2×18.3 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤80 | 130-600 | 55 | 22320 |

| 2LDT3645 | 3.6×4.5 | 2×16.2 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤100 | 170-650 | 55 | 22330 |

| 2LDT3661 | 3.6×6.1 | 2×21.96 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤100 | 175-720 | 75 | 26200 |

| 2LDT3673 | 3.6×7.3 | 2×26.3 | 3,4,5,-1,2. | 3-50;0.5-13 | ≤100 | 200-800 | 75 | 27350 |

Certifications

Packaging & Shipping

Our Advantages

Gain peace of mind with our extensive 1-year warranty, providing free parts replacement and repair services to guarantee seamless operations and complete customer satisfaction.

Company Profile

FAQ

Q1.Are you a manufacturing or trading company?A1.We are a manufacturer/ factory, established in 2010.Q2. How long is the warranty? Does your company supply the spare parts?A2.One year(Calculated from the equipment arrives the customer's side.). Spare parts for you at the lowest cost.Q3.What about Warranty? What will we do if the machine is broken down?A3.The warranty period for all of structural and mechanical equipment is one year. The warranty period for all electric motors is half one year. Wear parts are not covered by warranty unless the component part is found to be flawed.Q4.What is your payment method?A4.30% deposit in T/T advance, 70% balance before shipment.Q5. If I need the complete crushing plant can you help us to build it?A5.We can help you set up a complete production line and provide related professional advice. We had already built many mining projects in China & Overseas.Q6.What's the after sale service of your company?A6.We will provide foundation drawing and video to the clients for installation. Besides, we can provide guidance service for installation and operation of workers, etc.Q7. Can your company provide wearing parts?A7.We can deliver you the spare parts within 10 working days after your order. If your equipment are not manufactured by our company, please provide us the wearing parts drawing or number.Q8.What should we need to do for if we want to get a best quotation?A8.If you want us recommend a suitable type for you; please let us know the below informations:1).Mesh length: _____2).Mesh width: _____3).Mesh Height:_____4). Hole size _____5). Quantity:_______

Q9.What services are available?

A9.(1)Professional engineer design the production line for you.

(2)Pre-check and accept products before delivery.

(3)Professional technical guidance for installation

Related Products